Allied Furnaces Project Management is divided into the following verticals -

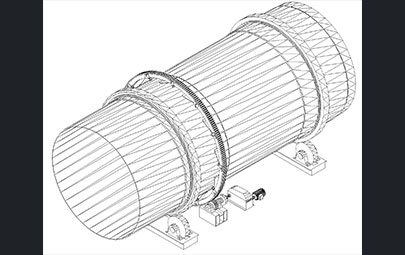

Design Engineering

Allied Furnaces is known for its design capabilities, due to which we revel in taking up challenging projects. We have our own team of chemical, structural, mechanical, electrical, instrument and refractory design engineers, who, using sophisticated software tools, are ready for any assignment. Plant 3D models and walk-through’s are created to get a thorough look and feel of the plant.

Project Engineering

Project management is the key to success of the project. The Project Department, headed by a General Manager; get the equipment manufactured from a set of dedicated fabricators, and procure the material from reputed vendors to complete the project. Using project monitoring tools, the projects are executed efficiently, economically and in a timely manner.

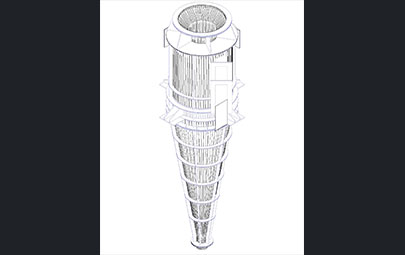

Erection

The fruits of a good design come out when the plant is erected. Allied Furnaces has its own team of supervisors who ensure the plant is erected as per the design. All aspects such as mechanical, structural, piping, electrical, instrumentation, refractory and PLC are supervised skilfully by our team of engineers. Man-power required for each of the above activities are sub-contracted to a team of specialised contractors.

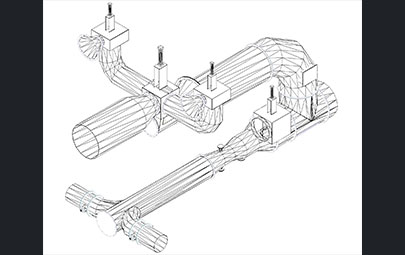

Commissioning

Allied Furnaces has a dedicated team of Commissioning Engineers trained in all aspects of plant operation and trouble shooting. They operate the plant 24x7, fine-tune the plant and also impart training to clients for plant take-over. We also undertake Operation and Maintenance contracts, so industries can focus on their core-competencies and leave the incinerator operation to the experts.